Exhibition Report | Guangshun Testing Makes a Splendid Appearance at the 15th Shenzhen International Battery Technology Exchange Conference/Exhibition

The three-day CIBF2023 Battery Exhibition is currently being held at the Shenzhen International Convention and Exhibition Center. At the booth of Guangshun Testing, customers are coming and going continuously. The number of visitors to the booth has reached over a thousand times. On the spot, the business team of Guangshun introduced in detail and comprehensively the company's technological innovation, product solutions and supporting products to the audience who stopped by. This not only received another affirmation from old customers but also won cooperation intentions from many new customers. Let's walk into the scene together and experience the wonderful moments of the exhibition.

Live coverage on-site

Weaknesses of helium detection technology

1.In the era of extreme precision manufacturing, how should helium leak detection be upgraded?

2.TWh era, how to alleviate the cost and procurement pressure brought about by the huge demand for helium?

3.Do you believe it? Can helium testing be cheaper than hydrogen testing?

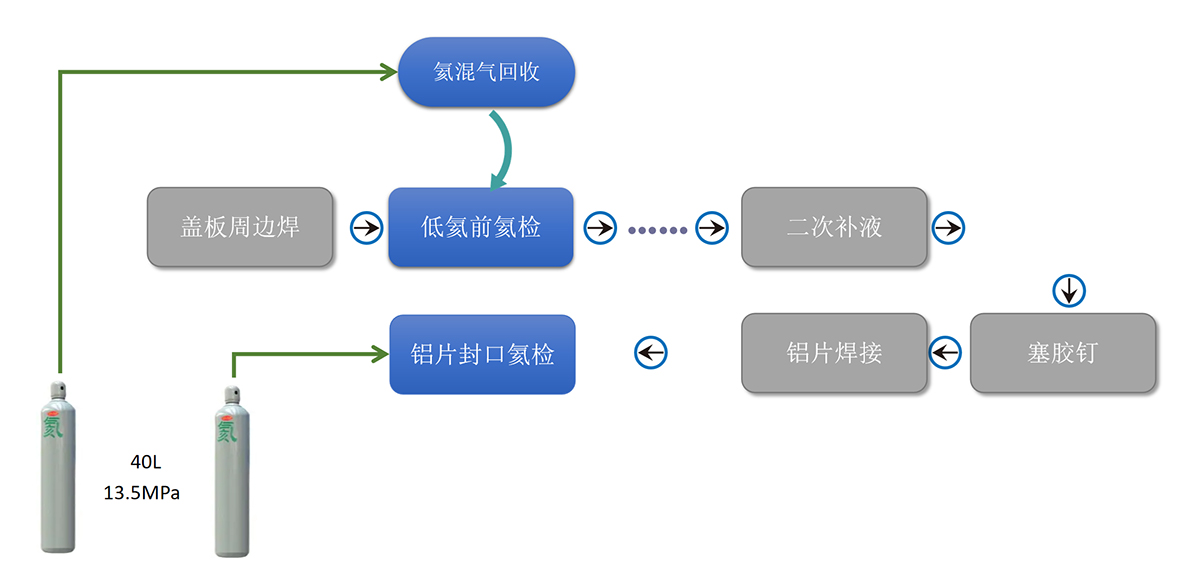

4.Regarding the IPX7/IPX8 test for PACK, why is helium inspection the only option available?

For the first three questions, the key lies in significantly reducing the helium usage and improving the quality.

It is well known that helium gas in our country is almost entirely dependent on imports. Under the current turbulent international situation, reducing helium consumption is of great significance:

1: Cost reduction. Not only the cost of helium gas is reduced, but also the corresponding management costs.

2:It can minimize the impact of helium shortage on production. Significantly reducing the procurement pressure during helium shortage.

3: It can reduce foreign exchange consumption.

4: It can reduce the dependence on helium from unfriendly countries.

Regarding the fourth issue, please refer to the PACK section for helium inspection scheme.

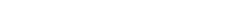

Guang Shun Battery Cell section helium inspection scheme

Take the production volume of 4.6 million square aluminum shell cells of model 27300110 as an example

In terms of improving the quality of battery cells, our helium inspection machine for filling and sealing can effectively test the sealing performance of sealing pins. It is currently the only solution available.

Due to the fact that gas detection is extremely sensitive to temperature and volume changes, the consistency of the test is poor. Only helium detection can meet the IPX7/8 requirements.

The next journey, the excitement continues!

➠ A team full of ideals and innovation is marching towards the position of the world's leading brand in helium detection field.

➠ It has provided professional helium detection equipment and services to over 10 Fortune 500 companies.

➠ The helium detection equipment has been exported to Japan, Southeast Asia, Europe and other places.

➠ It offers localized technical support to global customers.

Devote to developing more reliable helium detection methods, provide high-quality leak detection solutions for global customers, and assist customers in improving product quality.

-

Helium Leak Test "Gatekeepers": Seeing the Weight of Craftsmanship in the Tiniest DetailsLearn More

Helium Leak Test "Gatekeepers": Seeing the Weight of Craftsmanship in the Tiniest DetailsLearn More -

【Good News】Our company has won the third prize in the "Safety Production and First Aid" skills competition in 2025!Learn More

【Good News】Our company has won the third prize in the "Safety Production and First Aid" skills competition in 2025!Learn More -

【Hand in Hand, Win in the Year of the Horse | A Wonderful Review of Guangshun 2026 Theme Annual Meeting】Learn More

【Hand in Hand, Win in the Year of the Horse | A Wonderful Review of Guangshun 2026 Theme Annual Meeting】Learn More

Hotline: 4008-677-181

Hotline: 4008-677-181